Ken's Journal Pictou, NS |

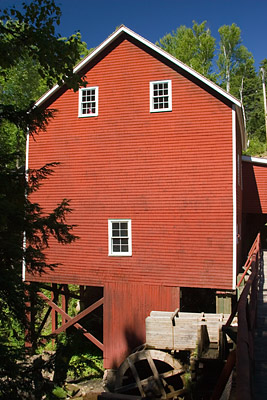

The Balmoral Grist Mill Museum - another of the Nova Scotia Museum system. This in a three-story mill with an overshot waterwheel. That means the water falls over the top of the waterwheel to drive it. |

|

| At the time I visited, the mill was not operating. Myself and another couple were given a tour by the new Miller - just hired, he'd started only two days before - he appeared to be in his early 30s at best. After the tour, we were cut loose to just wander the mill at will. Later I ran into the Miller again and we started talking. It seems that this gentleman worked part-time in the mill when he was in highschool and learned much of what there was to know about gristmills and milling grain. After graduating, he went to a local trade school for the building trades. While there, he hired on at another mill to restore it and get it running. After a number of years of part-time effort, he had that mill up and running. The Miller he had worked under at Balmoral, this mill, had passed on a few years ago and a new miller was hired by the province to run the museum. Apparently not well trained in gristmills, he seriously damaged the mill mechanism and was let go. Enter the new Miller. I had found the damage to the mechanism in the cellar and asked him about it - which is what started our conversation. When the mill is running, and the new miller hopes to make repairs and get it going soon, the mill runs everyday and sells all the grain milled as part of the museum activities. | |

From the base of the waterwheel looking up. |

From across the creek, halfway up the hill to the parking lot. |

The milling room. Shown is one of four sets of grindstones. |

There are four sets of grindstones that can be used. Each is a different type and finish of stone, used for milling different kinds of grain for different purposes. |

Part of the mechanism in the cellar. |

Another gear - up close. |

Here's the damage. The small gear does mesh with the large gear, but is only engaged when the large driving gear is stationary. The previous miller didn't fully understand the use of the wedge shown on the small gear and it once dropped into the large gear when the large gear was moving - you can see the damage to the teeth. All the teeth on both gears will have to be replaced before milling resumes. |

The hoppers on the third floor. From here, grain or partially milled flour is dropped into the appropriate grindstone. |

"For my part, I travel not to go anywhere, but to go. I travel for travel's sake. The great affair is to move." -- Robert Louis Stevenson |

Page 22 |

.

.